Free Shipping Within Canada on orders over $200!

Free Shipping Within Canada on orders over $200!

At Stokedman Studios, we create high-per-formance carbon fibre components and precision builds that balance strength, lightness, and reliability. Using techniques like vacuum bagging, resin infusion, and fast mould prototyping, we craft custom piec-es designed for consistent performance. From durable structural parts to refined, bespoke accents, our carbon fibre work blends advanced processes with careful craftsmanship—producing components that are both functional and visually striking. A project we undertook was designing and manufacturing a pair of Custom Freediving Fins. Our goal was to create fins that were lightweight, flexible, and efficient in the water, while also highlighting the technical processes that sets our work apart.

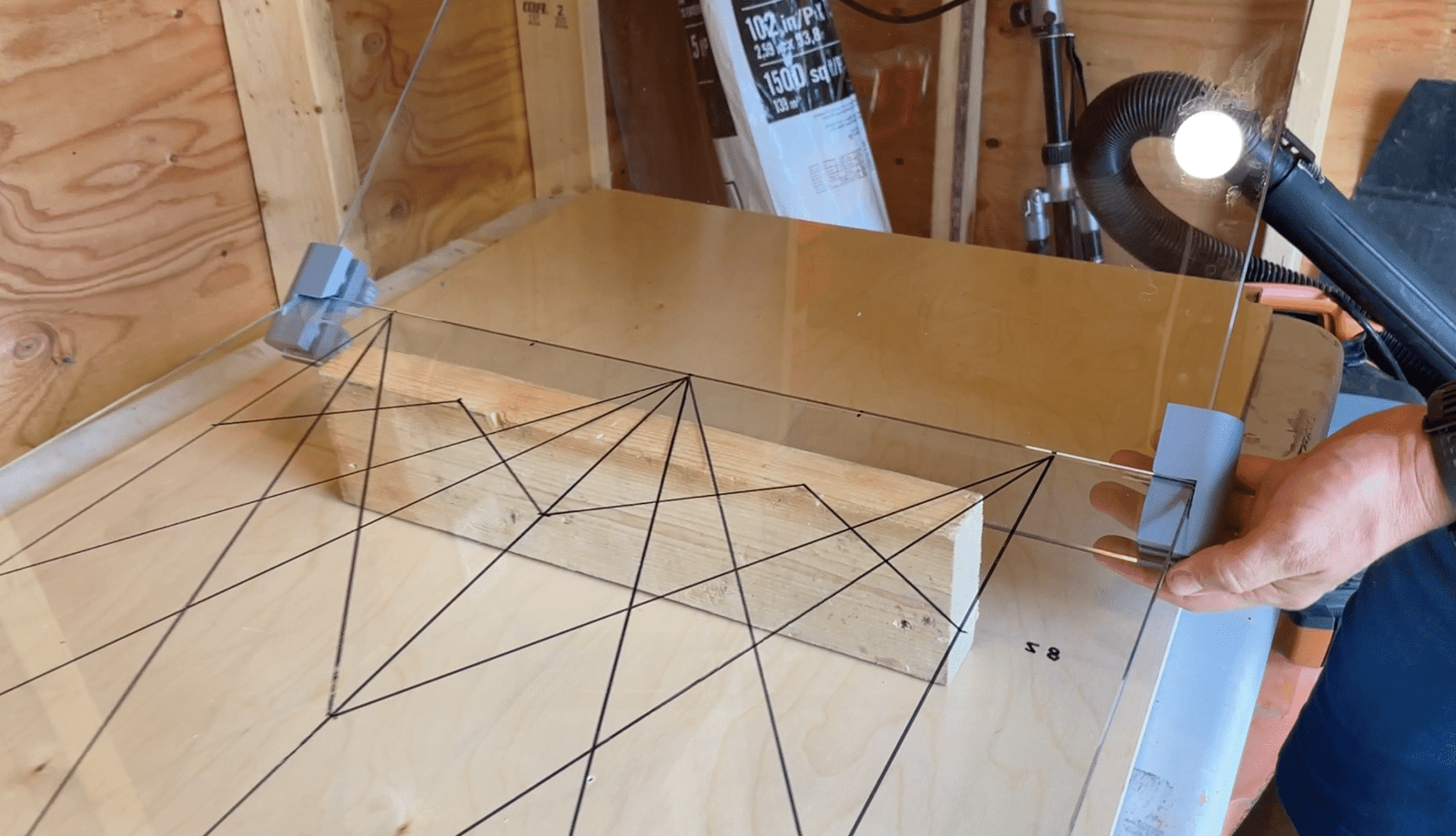

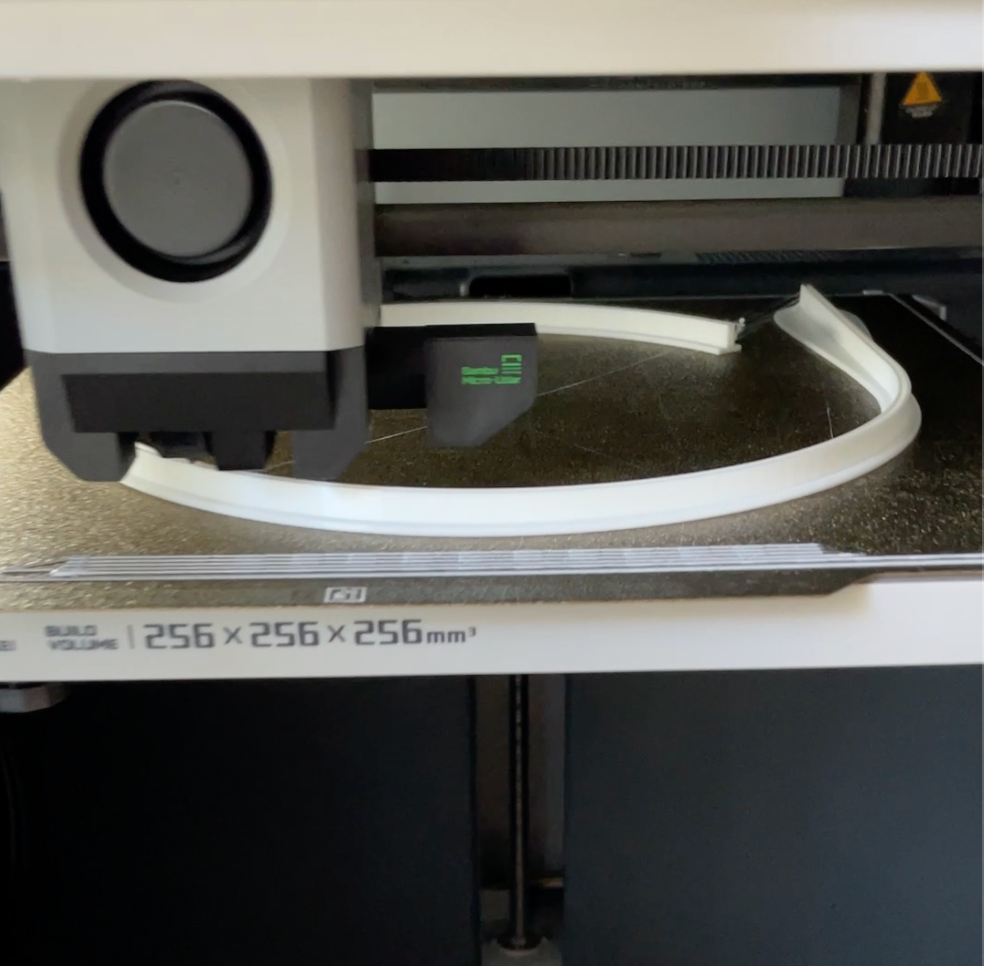

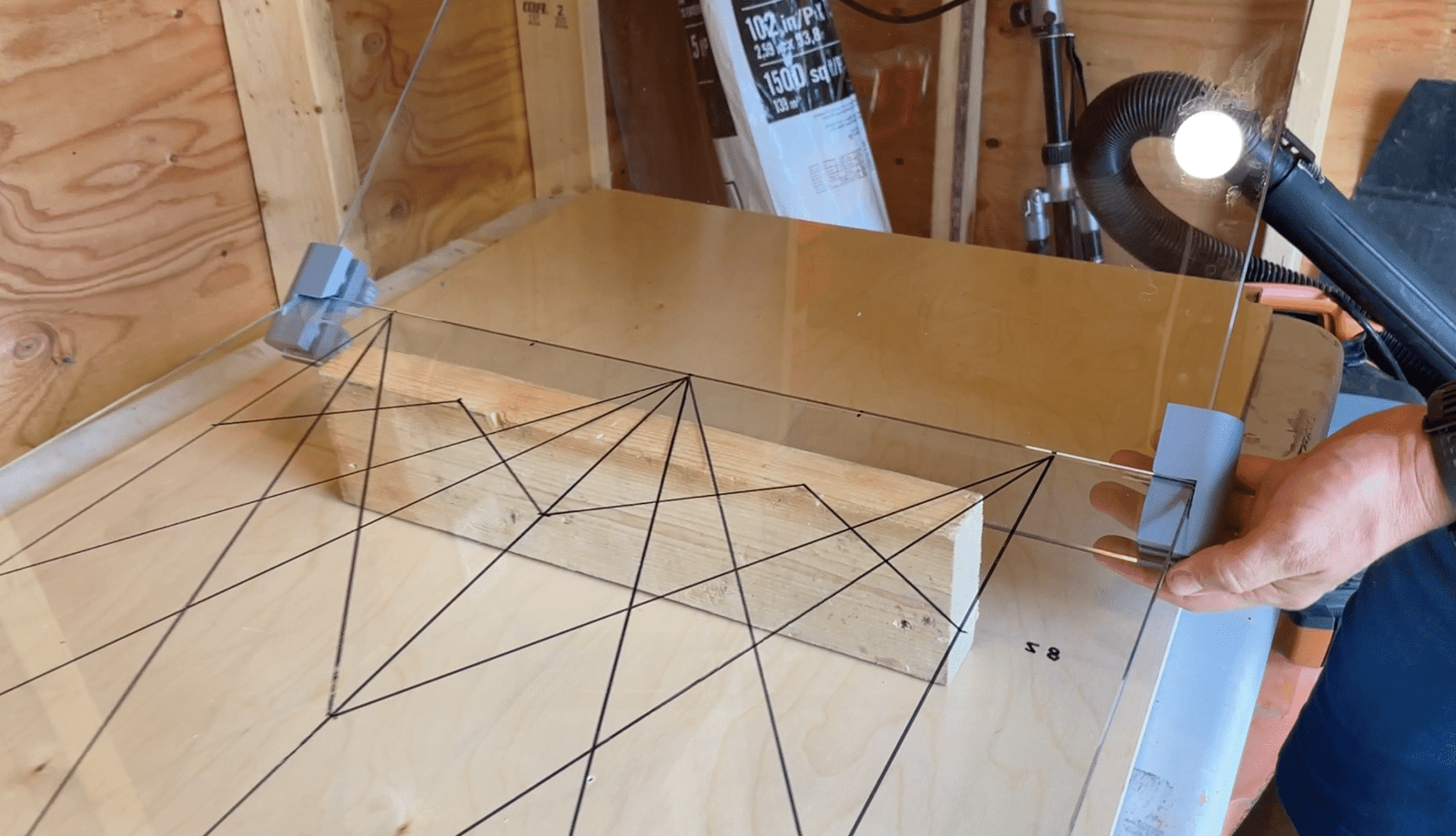

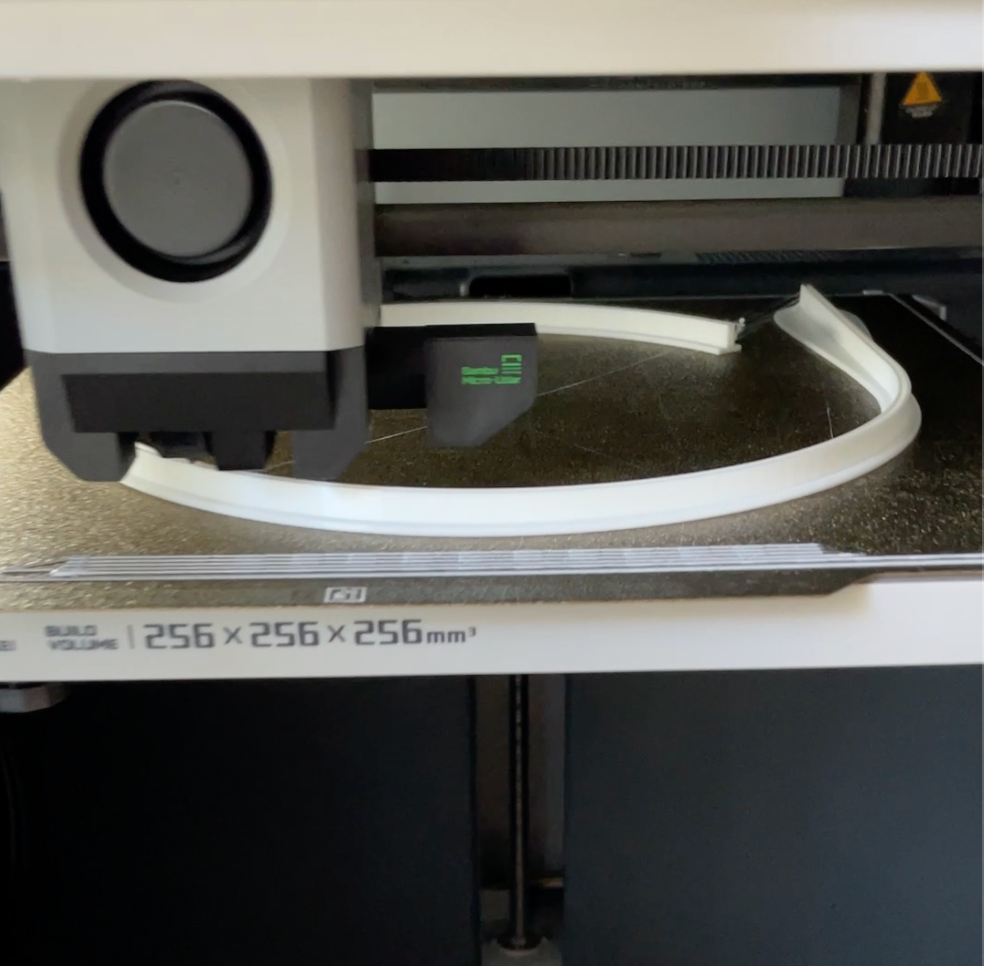

To achieve the exact surface and angle needed for the fins, we built a custom rig using glass panels and 3D printed hardware. This provided a perfectly smooth base and precise geometry for laying the carbon fibre sheets. Every detail—from the layup alignment to the finishing surface—was carefully controlled to optimise performance.

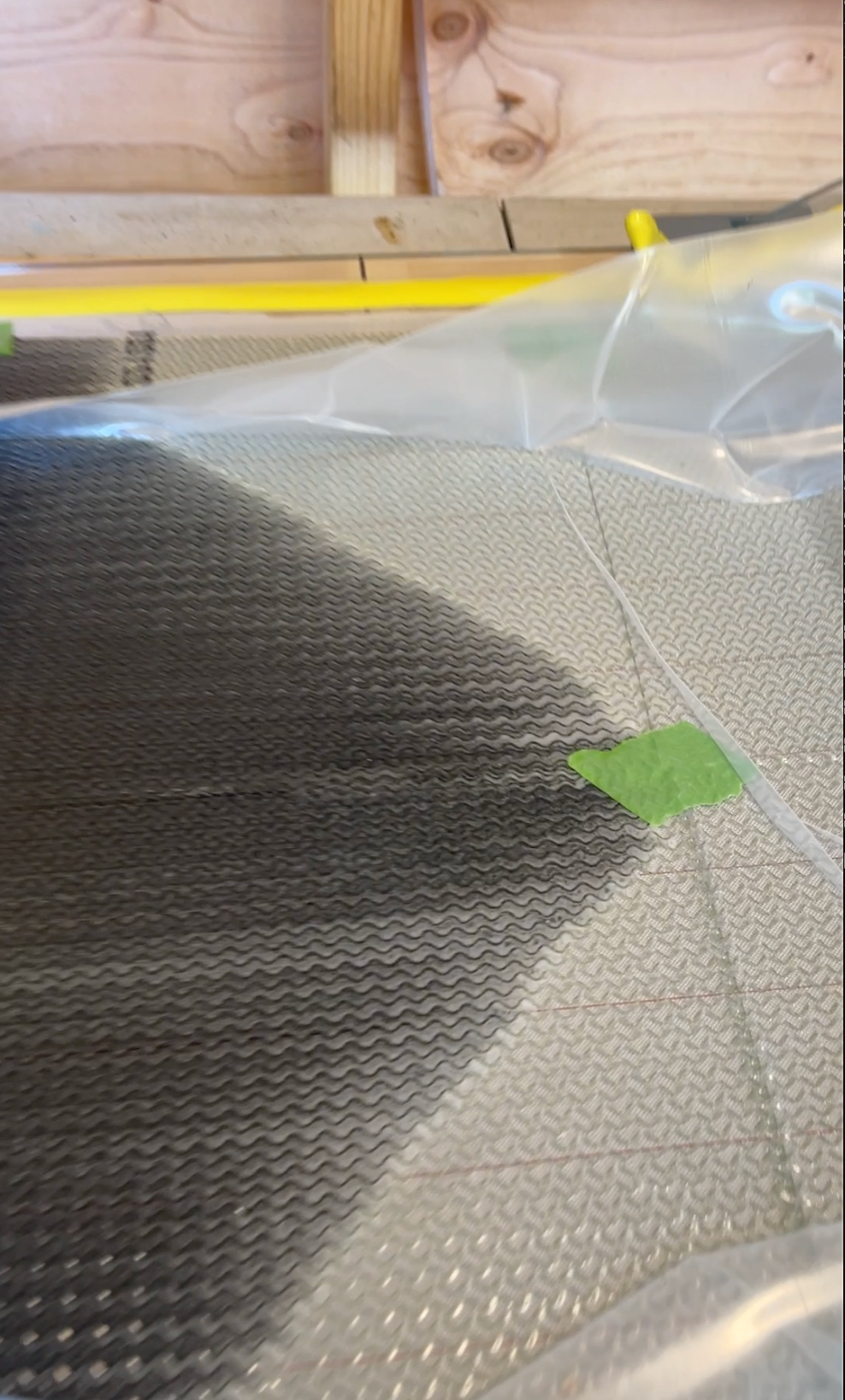

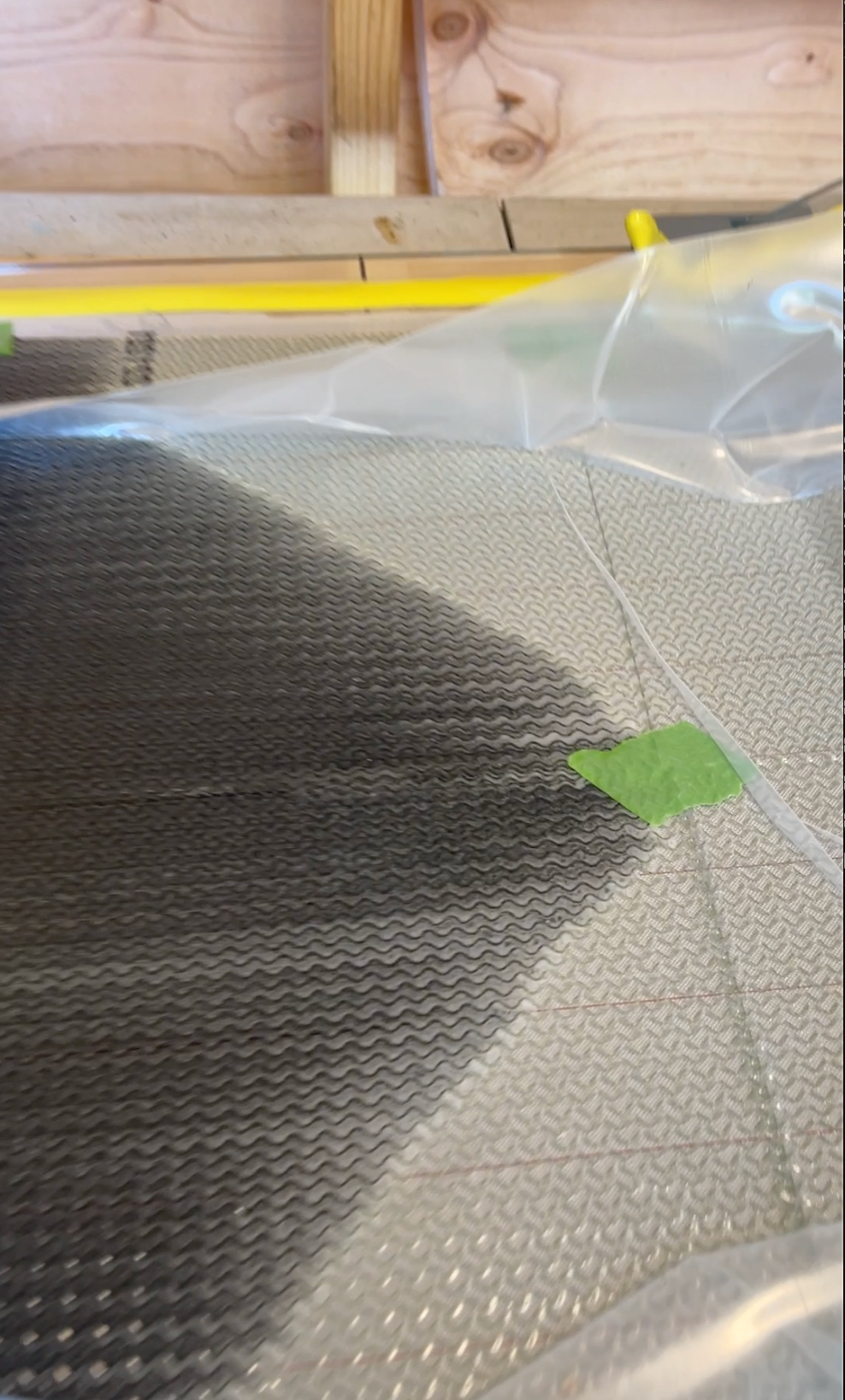

The carbon fibre layers were sealed inside a vacuum bag, a process that removes air pockets and compresses the fibres evenly. This ensures consistent strength across the entire part. Using resin infusion, epoxy resin

was drawn through the fibres under vacuum pressure, fully saturating the layup while maintaining a high fibre-to-resin ratio. The result: a fin blade that is lightweight yet exceptionally strong.

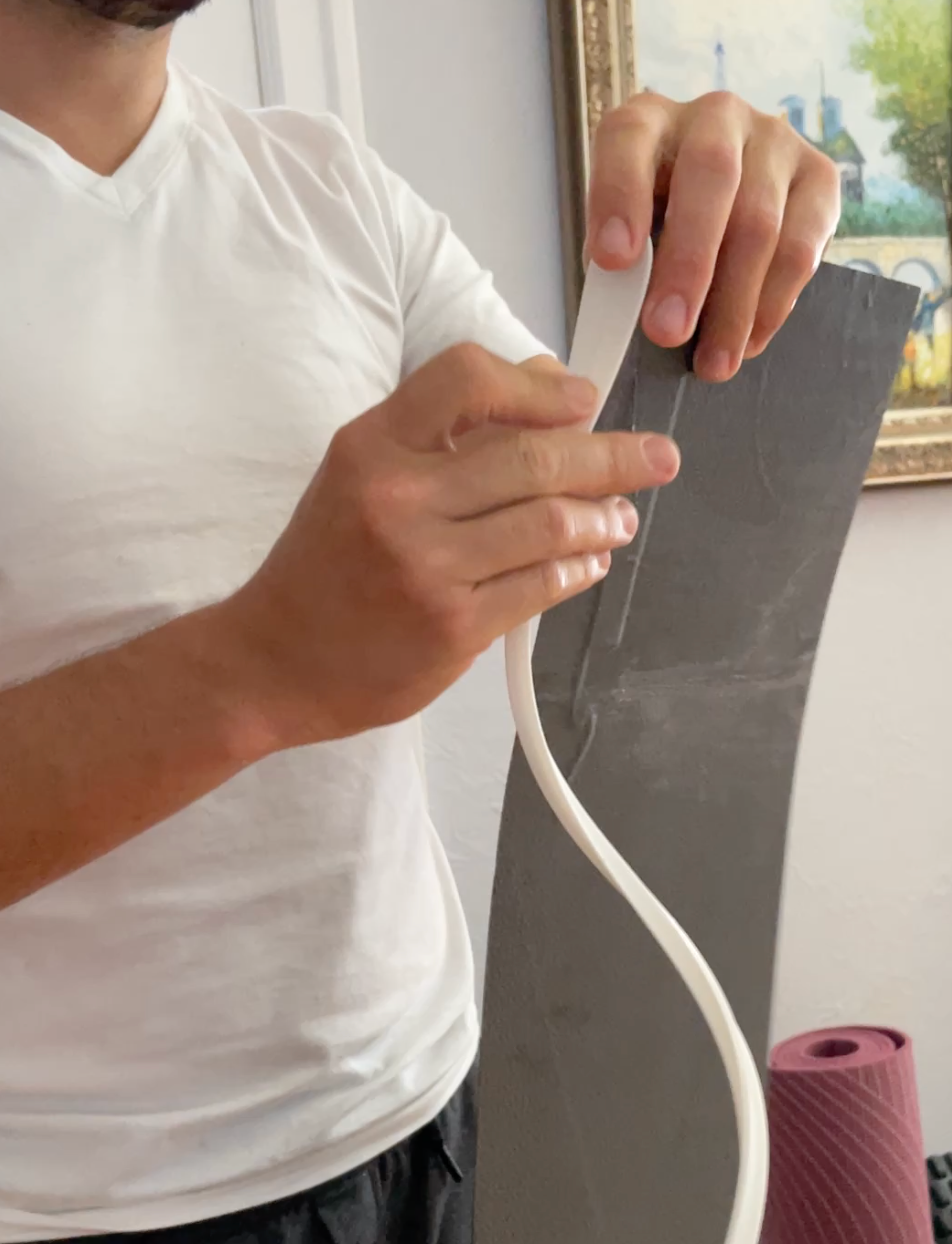

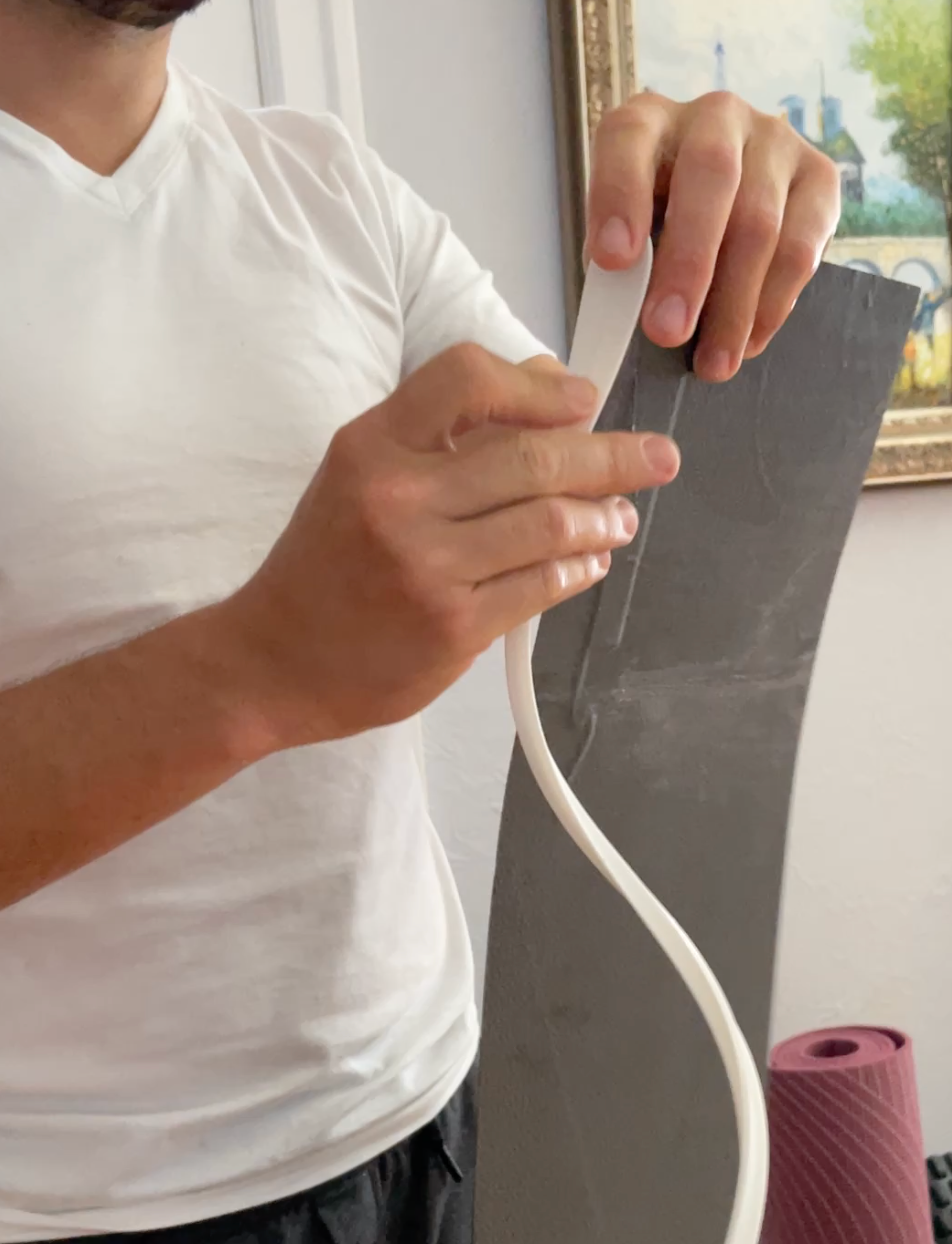

After curing, the fins were trimmed to exact dimensions, then ground and polished for a refined finish. We 3D printed custom blade rails and fitted the blades seamlessly into the foot pockets, completing a pair of fins that

combine high performance with striking aesthetics.

These freediving fins demonstrate what’s possible when advanced

composites meet precision engineering. They’re more than just fins—they’re proof of our ability to design and fabricate carbon fibre components that are strong, lightweight, and built to perform. Got a vision for a custom carbon fibre creation? Reach out and let’s make it a reality.

Do you have a project in mind or a product you’d like to develop? Let’s bring your ideas to life!