Free Shipping Within Canada on orders over $200!

Free Shipping Within Canada on orders over $200!

At Stokedman Studios, we turn big ideas into reality. Whether it’s a one-off prototype, custom car-bon fibre components, a fully functional product or a concept you’d like to mass produce, we thrive

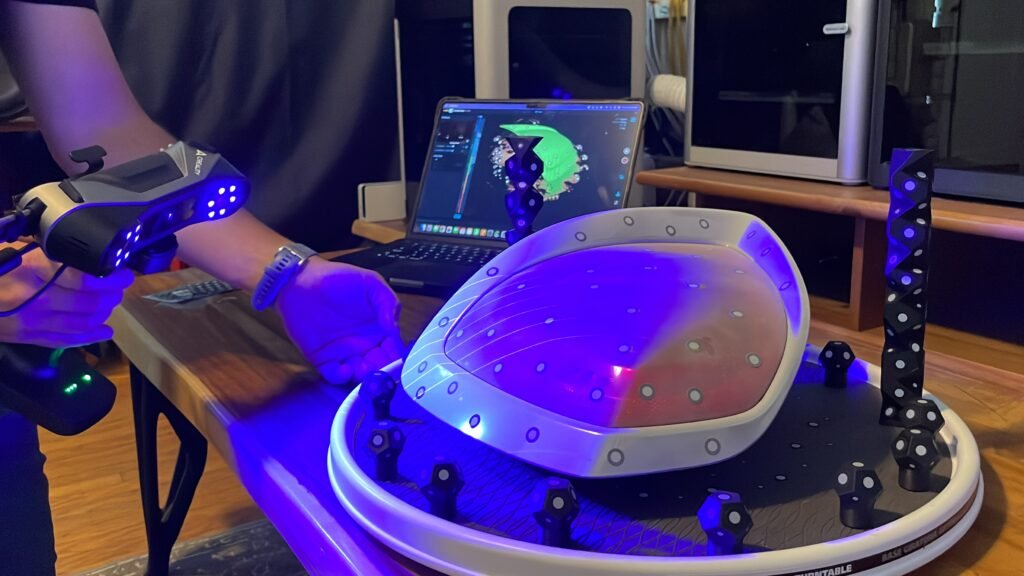

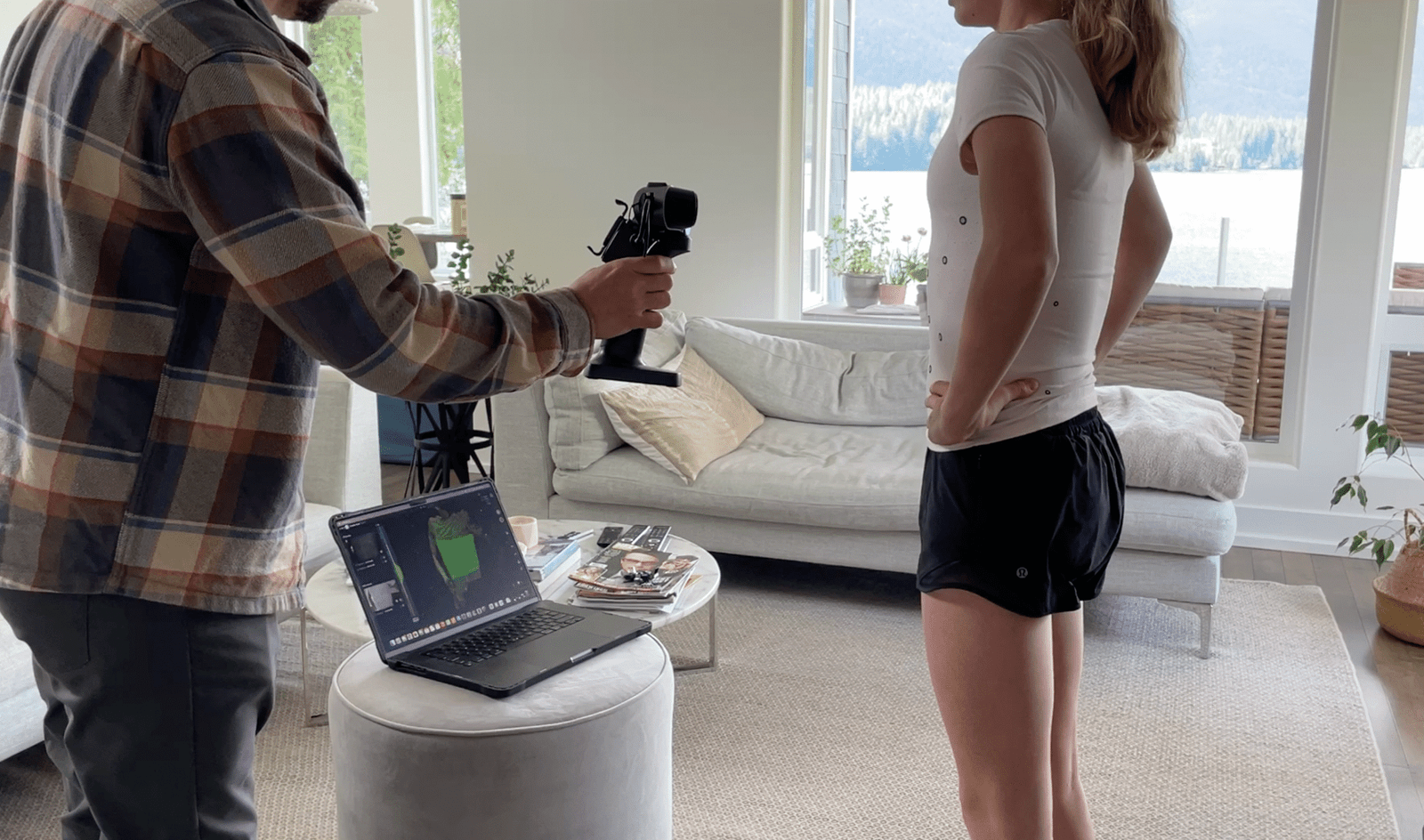

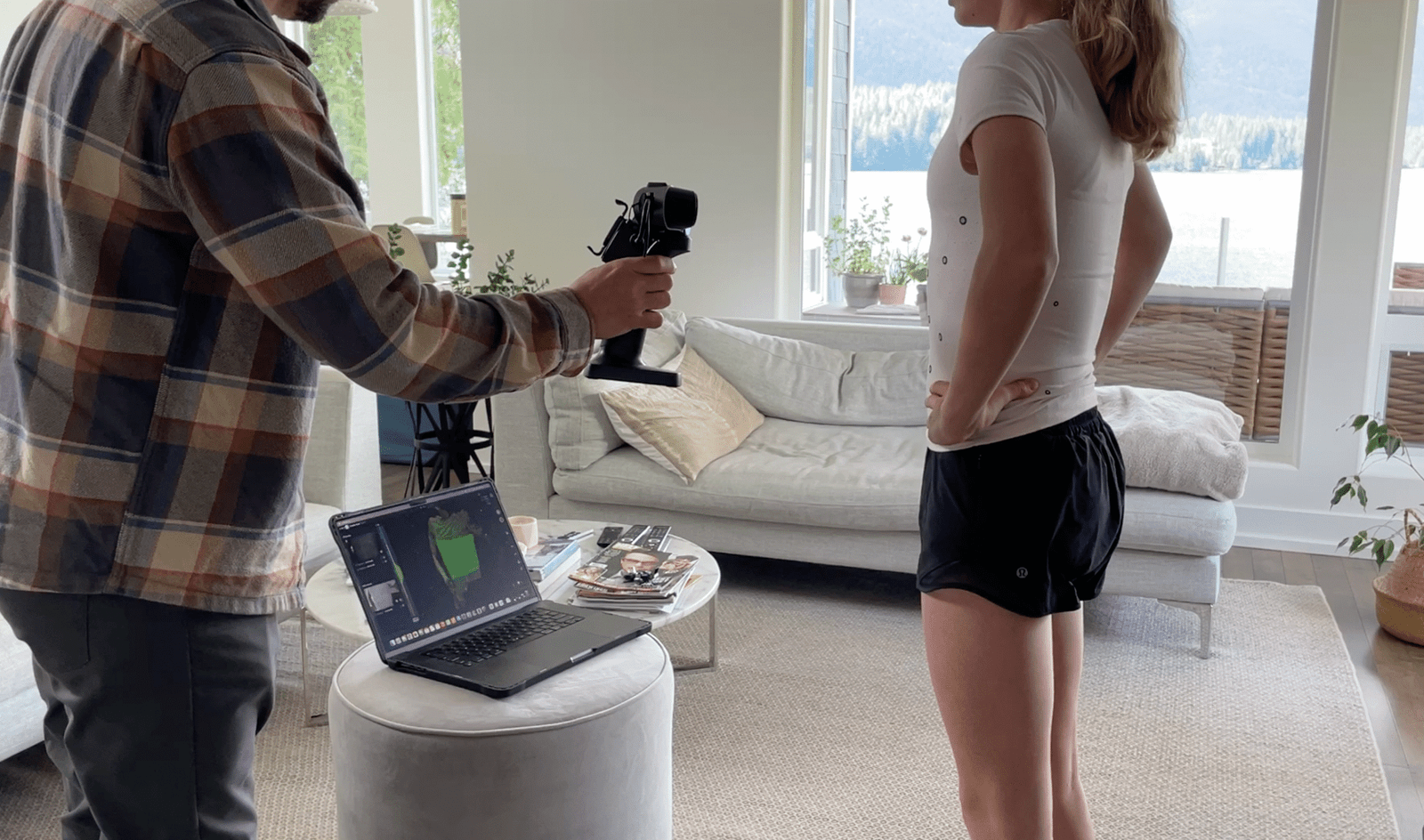

on custom projects that push boundaries. Our team combines advanced technology—like laser 3D scanning, CNC machining, 3D printing and composite work with hands-on craftsmanship to deliver precision, performance, and creativity in every build.

• Prototyping & Iteration – We help refine concepts by evaluating different designs and approaches.

• Material Exploration – From plastics and composites to carbon fibre, we select and work with the right material for your project.

• Laser 3D Scanning – Perfect for capturing complex shapes and ensuring a flawless fit.

• Custom Machining & Fabrication – Precision tools meet bold ideas.

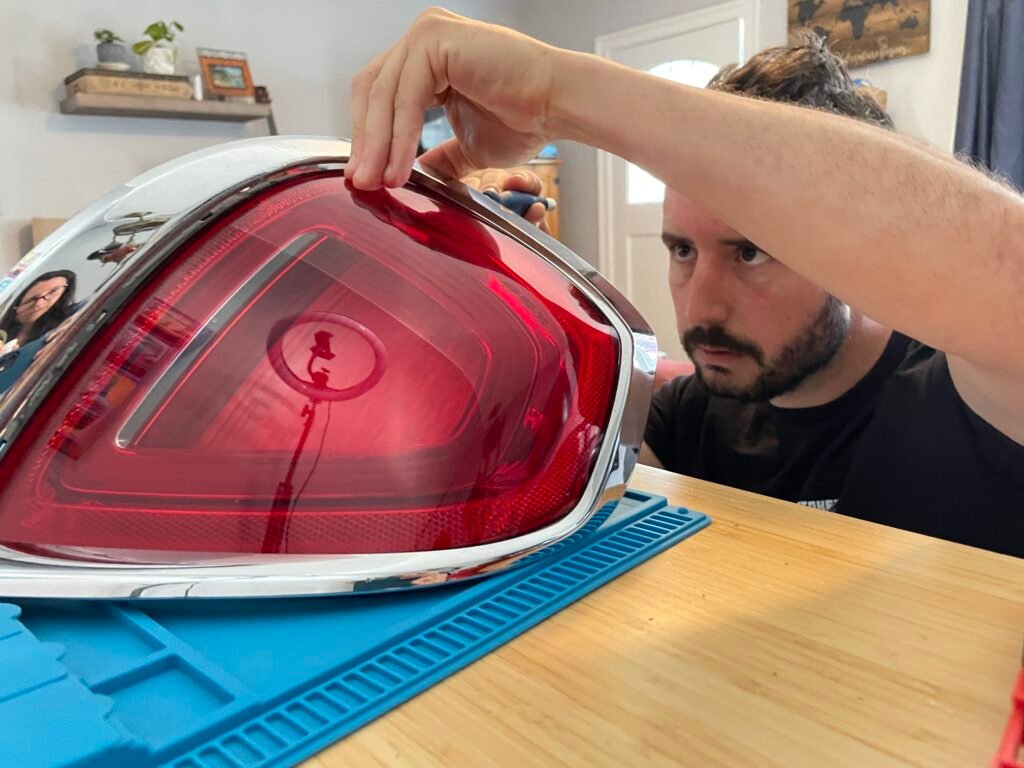

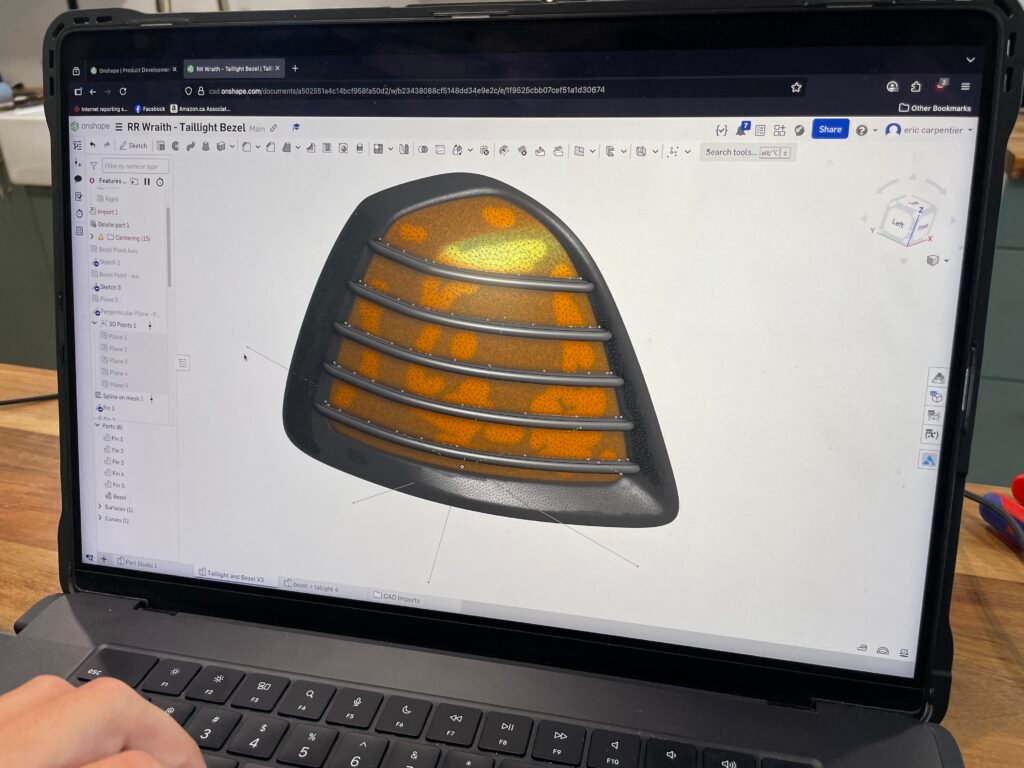

The rendering captured the spirit of the build, and our job was to engineer one of its key details—the tail light guards. We 3D scanned the existing tail lights to capture every contour with exact precision. From there, the original bezel was removed, laser scanned and digitally reimagined in CAD, where Eric modelled a replacement bezel with integrated off-road guards. The first prototype has already been 3D printed and test-fitted, laying the groundwork for the final piece. It’s a work in progress, but each step brings this unique concept closer to reality.

The rendering captured the spirit of the build, and our job was to engineer one of its key details—the tail light guards. We 3D scanned the existing tail lights to capture every contour with exact precision. From there, the original bezel was removed, laser scanned and digitally reimagined in CAD, where Eric modelled a replacement bezel with integrated off-road guards. The first prototype has already been 3D printed and test-fitted, laying the groundwork for the final piece. It’s a work in progress, but each step brings this unique concept closer to reality.

This project began when a family approached us with a heartfelt request: they wanted their daughter, who has an enlarged spleen, to be able to play sports safely without fear of impact. Off-the-shelf options didn’t provide the right protection or fit, so they turned to us for a fully custom solution.

Our studio specializes in high-performance gear, working with advanced materials like carbon fibre, Kevlar, and ultra-strong composites to deliver

parts that are lightweight, durable, and engineered for excellence. We also create bespoke high-end accents, combining precision raftsmanship with refined aesthetics. Equipped with vacuum bagging systems, resin infusion setups, and fast

mould prototyping capabilities, we produce parts with careful attention to

strength, fit, and finish—whether for functional performance applications or

luxury details.

Carbon Fibre Work

Our studio specializes in high-performance gear, working with advanced materials like carbon fibre, Kevlar, and ultra-strong composites to deliver

parts that are lightweight, durable, and engineered for excellence. We also create bespoke high-end accents, combining precision raftsmanship with refined aesthetics. Equipped with vacuum bagging systems, resin infusion setups, and fast

mould prototyping capabilities, we produce parts with careful attention to

strength, fit, and finish—whether for functional performance applications or

luxury details.

Do you have a project in mind or a product you’d like to develop? Let’s bring your ideas to life!

Do you have a project in mind or a product you’d like to develop? Let’s bring your ideas to life!